Packaging & Circular Economy

Strategy

KDP supports the reuse, recycling, repurposing and composting of our products and packaging in support of a more circular economy. Driving the transition to a circular economy is complex and requires scalable systems change. Therefore, individual and company responsibility as well as collective action are critical to advancing effective and efficient policy solutions, investing in infrastructure and modernization and engaging consumers to act in more sustainable ways.

Packaging & Circular Economy Strategy

Design & Innovation

▪ Material Reduction & Efficiencies

▪ Packaging Optimization for Recyclability,

Compostability & Reuse

▪ Alternatives to Virgin Plastic

Advocacy, Infrastructure & Partnerships

▪ EPR Programs

▪ Recycler & Community Engagement

▪ Consumer Education & Access to Recycling,

Composting & Reuse

Resource Recovery

▪ Waste Reduction in our Operations

▪ Take-Back Programs

▪ Strengthening End Markets for Recycled Materials

Our strategy to support a more circular economy aims to use more sustainable packaging materials and designs that use less virgin plastic. This means incorporating more PCR content where possible, working to reduce or eliminate unnecessary materials, redesigning packaging to be compatible with recycling and composting systems and exploring reuse and refillable packaging models.

Beyond KDP’s design innovations, collective action is critical to advance effective and efficient policy solutions, such as well-designed Extended Producer Responsibility (EPR) programs, invest in infrastructure modernization and engage consumers to act in more sustainable ways. To help make this happen, we partner with a wide variety of external organizations, including state/provincial and municipal government leaders, recyclers, non-governmental organizations (NGOs), industry peers and suppliers.

We also strive to improve resource recovery so that valuable materials are reused, recycled and composted, rather than ending up in landfills. Each of our manufacturing sites supports this commitment through production optimization and investing in reducing, reusing and recycling materials and resources. To further support consumers, we now offer a take-back recycling program intended for consumers who live in communities where Keurig K-Cup pods are not currently accepted for recycling. To help close the loop of the circular economy, we help strengthen end markets for recycled materials by purchasing and incorporating PCR content where we can across our packaging portfolio and in our coffee makers.

Management Approach

KDP’s cross-functional teams across all geographies, including Procurement, Research & Development (R&D), Packaging Innovation, Operations, Government Affairs and Sustainability, collaborate to advance our packaging and circular economy goals.

We leverage third-party design standards and guidelines, such as the Association of Plastic Recyclers (APR) Design Guide® for Plastics Recyclability, to inform our packaging’s compatibility with recycling infrastructure against industry accepted criteria. We track and measure the impact of our efforts by reporting them through organizations including the Global Commitment, led by the Ellen MacArthur Foundation (EMF) in collaboration with the UN Environment Programme, the Canada Plastics Pact and World Wildlife Fund (WWF)’s ReSource: Plastic.

We also work with regulatory agencies to meet and report on various packaging compliance regulations across North America, such as EPR programs, Deposit Return Systems (DRS) and minimum recycled content requirements in place in certain jurisdictions. We continue to update and modernize our technology and data reporting systems so we can optimize our measurement and reporting for compliance and regulatory requirements.

Unveiled our vision for new K-Rounds plastic- and aluminum-free pods as well as a new brewing system, the Keurig Alta brewer

of packaging converted

to be recyclable or

compostable

virgin plastic reduction across our packaging portfolio since 2019

committed in support of a

more circular economy

since 2014

Secured acceptance of K-Cup pods into Canadian province-run curbside collection programs in Ontario and Quebec

Launched K-Cycle At Home, a new mail-back program aimed at expanding K-Cup pod recycling access for consumers

We are working to improve packaging materials and design, while collaborating and investing in infrastructure in support of a circular economy.

- In 2024, we announced that we would be launching K-Rounds plastic- and aluminum-free pods as well as a new brewing system, the Keurig Alta brewer. K-Rounds pods are created from roasted coffee beans that are ground, pressed and wrapped in a proprietary, protective plant-based coating preserving the coffee’s flavor and aroma. We are currently in the beta testing phase, using a prototype brewer to gather insights from real-world homes and consumers that will help us fine-tune the performance, quality and design of the system.

- We continue to incorporate recycled plastic into select beverage bottles by using bottles made from recycled polyethylene terephthalate (PET) plastic. Current products in bottles made of recycled PET plastic include Bai, Core Hydration+, Core Hydration, Snapple 16 oz. and 20 oz., Mistic Juice Drink 16 oz. Aguafiel and Peñafiel single serve bottles each contain a minimum of 30% recycled PET.

- To reduce the use of unnecessary materials, we have lightweighted nearly all of our K-Cup pods by reducing the plastic of each pod by 18%, compared to the original design.

- Through continuous improvement efforts, we maximized space within our 80 count K-Cup pod packaging by arranging pods in a nested format. For one partner, this practice resulted in a 30% increase in boxes shipped per pallet, a reduction of 491 truckload shipments and a 35% decrease in packaging material used.

- Our black K-Mini, K-Mini Plus, K-Café Essentials, K-Express Essentials, K-Cafe Smart, K-Slim and K-Compact brewers contain at least 50% PCR content and our K-Supreme Plus, K-Supreme Smart brewers contain at least 30% PCR content.

- To help improve the recyclability of our packaging, we converted the majority of Bai and all of Mr & Mrs T 1 liter and 1.75 liter products and Rose’s products to meet the APR Design Guide® for Plastics Recyclability Preferred criteria for circularity status. This change increased KDP’s proportion of plastic packaging that has been designed to achieve a Preferred status as outlined within the APR Design Guide® for Plastics Recyclability by 2.76%.

- We strive to make ‘recycle right’ instructions more visible to consumers on pack. For example, as part of the redesign of our Snapple bottles, our packaging team developed a contoured bottle with increased label space for consumer recycling instructions.

Refillable Packaging

We continue to advance our work on refillable packaging by exploring new partnerships that are critical to develop and scale reuse and refillable delivery models.

- Since 2023, we have been members of the Green Sports Alliance (GSA), a nonprofit that convenes and educates professional and collegiate sports industries, the entertainment industry and their partners for a more resilient and sustainable future. As part of the membership, KDP funded the Reuse Playbook that was published in 2024, which explores the current landscape in the U.S. for reusable opportunities and actions that venues and brands can take.

- In Fall 2024, KDP and the Chicago Bears collaborated with the Soldier Field site operator ASM Global, the Soldier Field hospitality partner Levy and the reusable drink and foodware logistics company Bold Reuse, to launch a unique reusable cup program in the United Club at Soldier Field, one of the first in the National Football League (NFL).

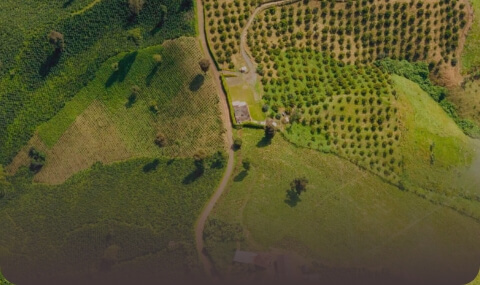

- We continue to offer refillable glass bottles in Mexico where the infrastructure for collection, sanitation and refill currently exists. Specifically, our plant in Tehuacán, Mexico has over 70 years of experience producing and managing our refillable glass bottles and recently expanded production to increase our capacity of refillable glass bottles.

-

EPR Programs: We advocate for policies at all levels of government to accelerate the development of a circular economy for packaging materials, particularly for the modernization and standardization of recycling and industrial composting infrastructure. Across North America, a patchwork of regulations, inadequate investment and lack of minimum performance standards are preventing economies of scale in our recycling system* and confusing consumers**. That is why we support smart policy solutions, such as well-designed EPR programs, that are focused on efficient and equitable ways to increase material recovery, while reducing the economic and environmental costs of disposal. Read more here.

- Canada: We have been engaged with leading Producer Responsibility Organizations and regulators that are responsible for the implementation of expanded municipal recycling programs across the country. This work has led to the acceptance of K-Cup pods into Canadian province-run recycling programs in Ontario and Quebec.

- U.S.: KDP played a key role in launching the country’s first Producer Responsibility Organization, Circular Action Alliance, and is the only organization approved to implement U.S. EPR laws for paper and packaging and is operating as the sole Producer Responsibility Organization in California, Colorado, Maryland, Minnesota and Oregon. In 2024, we also joined forces with other consumer packaged goods producers and retailers through the EPR Leadership Forum to advocate for well-designed EPR for packaging in the U.S.

- Municipal Recycling Facilities Engagement: We work directly with recycling facility operators in specific communities to encourage acceptance of our packaging materials and to understand opportunities for technology improvements. In 2024, we continued our efforts by working collaboratively through programs like The Recycling Partnership’s Polypropylene Coalition and American Beverage Association’s Every Bottle Back initiative to award grant funding to specific facilities and communities with the aim to improve infrastructure, capacity and education to ultimately improve access to recycling.

- Consumer Education & Access: Each individual community recycling program in the U.S. has a unique list of materials and formats that they accept for recycling. This lack of recycling acceptance harmonization has resulted in inconsistencies across municipalities in both what consumers can recycle and how that information is communicated to consumers. In early 2025, we sponsored the I Recycle Phoenix event, hosted by Keep Phoenix Beautiful. More than 1,000 cars participated in this drive-through recycling initiative, where Phoenix residents dropped off items ranging from old electronics and building materials to bicycles and soft plastic bags. Informative flyers highlighting the recycling of K-Cup pods were included with broader community recycling information distributed at the event with the aim to keep many items out of landfill, including plastic packaging.

*According to The Recycling Partnership, the U.S. recycling system is not a unified or governmental entity, but rather a network of more than 9,000 separate local recycling programs. Each individual program has specific parameters for which materials can be recycled and municipalities collect recyclables in different ways.

**60% of people are confused about how and what to recycle, according to The Recycling Partnership.

Partnering to Impact Systems Change

Since 2014, KDP has committed more than $50 million in support of a more circular economy through collaborative projects, partnerships and investments in communities across North America. In fact, we have co-founded three organizations that amplify both dollars and action to enhance recycling infrastructure and educate consumers on proper recycling behaviors.

- The Recycling Partnership’s Polypropylene Recycling Coalition: Since its start in 2020, $22 million has been awarded in grant funding across 66 facilities to improve infrastructure, capacity and education, enabling over 50 million people in the U.S. to have new or improved access to polypropylene recycling.

- American Beverage Association’s Every Bottle Back Initiative: At year-end 2024, commitments made in 50 communities across the U.S. to modernize recycling facilities are estimated to yield 707 million additional pounds of PET plastic to be recycled over the next 10 years, which equates to approximately a 3% increase of additional recycled PET plastic over that time period.

- Circular Plastics Taskforce: In 2024, 30 circularity leaders from across the industry mobilized to advance the circular economy in Canada. Projects underway in 2024, which are valued at an estimated $700,000 CAD, aim to optimize plastics recycling along the value chain with a focus on challenging resins and formats.

- In our manufacturing facilities and throughout our supply chain, we are focused on waste reduction and resource recovery across all processes and functions. Each of our sites supports this commitment through production optimization as well as investing in the reduction, reuse and recycling of materials and resources. We have also increased our focus of source separation and best management practices at targeted manufacturing sites. For example, one of our largest carbonated soft drinks (CSD) facilities successfully reduced landfill waste by 35% in 2024, compared to 2023, through employee education and improved signage to encourage proper waste segregation and recovery of recyclable materials.

- Beyond our design and manufacturing capabilities, we are committed to supporting consumers, customers and partners in their resource recovery efforts. In late 2024, we launched a new mail-back program to expand recycling access for consumers who live in communities that are not currently accepting K-Cup pods in their local recycling programs.

- To support our commercial customers in resource recovery, we continue to offer recycling and composting services for high-volume operations, such as offices, universities and healthcare facilities. Since the inception of the program in 2011, nearly 6 million pounds of pods collected through the program have been kept out of landfills, a small but important step in contributing to a more circular economy.

- For our Keurig brewers, we continue to offer programs in the U.S. and Canada to select retailers to send in-store returned coffee makers to be recycled through a third-party partner. In Canada, we also offer a recycling program for our commercial brewers.

- We continue to help strengthen viable end markets of recycled materials by purchasing and using PCR in products. For example, we produce select products in bottles made from recycled PET plastic and incorporate PCR into specific coffee maker models.